NdFeB magnets (also known as NdFeB magnets) are permanent magnets made of an alloy composed of neodymium, iron, and boron, forming an Nd2Fe14B tetragonal crystal structure. It is the most widely used type of rare earth magnet.

NdFeB magnets can be divided into bonded NdFeB and sintered NdFeB. Bonding is injection molding while sintering is vacuum molding through high-temperature heating.

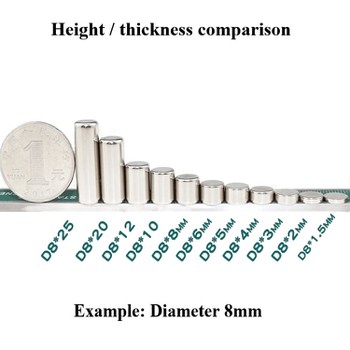

Its material grade is N35-N52;

Common processing shapes: round, square, punched, magnetic tile, magnetic rod, convex, trapezoid;

Surface treatment: nickel plating, zinc plating, gold plating, epoxy resin plating, etc.

neodymium magnets Applications

Top 10 Uses for Neodymium Magnets

As a leading magnet supplier, we often get questions about the practical uses of our products. Recognized for its superior strength, the neodymium magnet has found its way into countless applications, many of which feature prominently in our everyday lives.

To shine a light on the versatility of these powerful magnets, we're sharing the top ten everyday uses of neodymium magnets.

Neodymium magnets are integral components in many electronic devices we use daily. They can be found in hard disk drives, mobile phones, headphones, and speakers. Thanks to their compact size and high magnetic strength, they contribute significantly to the miniaturization and performance enhancement of electronic devices.

2. Magnetic Fasteners

Have you ever wondered how your purse or bag maintains a secure close without a traditional lock? The secret is often a small, yet strong neodymium magnet. These magnets provide a secure closure and easy access, making them perfect for various accessories and jewelry.

3. Fridge Magnets

While your typical fridge magnet might not require the strength of a neodymium magnet, there are high-end decorative and utility fridge magnets that do. These magnets can hold more weight, like your child's latest artistic masterpiece or important notes and lists.

4. DIY Projects

For the avid DIYer, neodymium magnets offer endless possibilities. They can be used to create magnetic spice racks, and knife holders, or even to organize tools in the garage.

5. Healthcare

Neodymium magnets play a crucial role in healthcare. They are integral components in MRI machines and are used in various therapies, including magnetic therapy for pain relief.

6. Education

Neodymium magnets are fantastic educational tools. They are often used in science classes to demonstrate the properties of magnetism and to spark curiosity in young minds.

7. Renewable Energy

In the world of renewable energy, neodymium magnets are game-changers. They are vital components in the generators of wind turbines and in electric vehicle motors, contributing to the green energy movement.

8. Jewelry

In the jewelry industry, neodymium magnets are often used in magnetic jewelry clasps. They provide a strong hold, ensuring that your valuable pieces remain secure.

9. Door Catches

For a sleek, modern look, some doors, particularly cabinets, employ neodymium magnets as door catches. They provide a silent and effective way to keep doors closed without traditional latches.

10. Fishing

Magnet fishing has become a popular hobby, and neodymium fishing magnets are at the heart of it. Their excellent magnetic force enables hobbyists to recover various metal objects from bodies of water.

Neodymium magnets have replaced alnico and ferrite magnets in many of the myriad applications in modern technology where strong permanent magnets are required because their greater strength allows the use of smaller, lighter magnets for a given application. Some examples are:

Head actuators for computer hard disks. Mechanical e-cigarette firing switches

Locks for doors Loudspeakers and headphones

Electric motors Voice coil

Magnetic bearings and couplings Benchtop NMR spectrometers

Cordless tools Lifting and compressor motors

Servom. tors Synchronous motors

Spindle and stepper motors Electrical power steering

Actuators Retail media case decouplers[clarification needed]

Mobile phone speakers, haptic feedback, and auto-focus actuators

Identifying precious metals in various objects (cutlery, coins, jewelry, etc.)

Electric generators for wind turbines (only those with permanent magnet excitation)

Drive motors for hybrid and electric vehicles(The electric motors of each Toyota Prius require one kilogram (2.2 lb) of neodymium).

In process industries, powerful neodymium magnets are used to catch foreign bodies and protect products and processes

Benefits of Neodymium Magnets

Neodymium magnets outdo samarium cobalt magnets in terms of cost and strength, which makes them a popular choice for so many applications. Therefore, neo-magnets are used more frequently in a multitude of applications. An important factor for magnets to have in carrying out various functions is to have magnetic permanence, or the ability to retain magnetism under circumstances such as heat, electric fields, corrosion, and vibration. Applications in which magnetic permanence is highly critical include medical, automotive, and industrial equipment.

There are two main processes of manufacturing neo magnets. The first is classical powder metallurgy or the sintered metal method. This process involves using a furnace to melt raw materials and mix them, and then placing the molten material into a mold as it cools, solidifies, and takes on the mold’s shape. Rapid solidification is the process of using a melt-spinning technique to create a neodymium magnet. Melt spinning is a process that quickly cools molten raw material with a wheel that is cooled internally by water or liquid nitrogen and rotated. The liquid is then dripped onto the wheel, where it rapidly cools and solidifies.