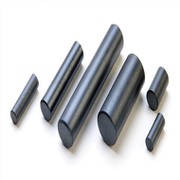

Ferrite Horseshoe Magnet

Although the performance of ferrite materials is closely related to the four links of raw materials, formula, molding and sintering, it is also a key research issue of ferrite process principles. However, the properties of ferrite materials made under the same formula raw materials and process are quite different. This is mainly due to the difference in specific quality in each specific process link (such as ball milling, molding and sintering, etc.). Therefore, how to give full play to the role of each process link and improve the quality is a key issue in improving ferrite materials.

Ferrite Horseshoe Magnet

Although the performance of ferrite materials is closely related to the four links of raw materials, formula, molding and sintering, it is also a key research issue of ferrite process principles. However, the properties of ferrite materials made under the same formula raw materials and process are quite different. This is mainly due to the difference in specific quality in each specific process link (such as ball milling, molding and sintering, etc.). Therefore, how to give full play to the role of each process link and improve the quality is a key issue in improving ferrite materials.

Usually, ferrite polycrystalline materials are manufactured by powder metallurgy method, and the specific manufacturing process flow.

In recent years, the large-scale production technology and equipment of ferrite materials have made greater development abroad. Japan's TDK company adopts a closed pipeline production method from batching to ferriteization of materials, which purifies the production environment, improves production efficiency, improves labor conditions, and improves the consistency and stability of ferrite material properties. In order to ensure the guarantee, it has reached the requirements of large-scale modern industry. In addition, in order to obtain higher-performance ferrite materials, chemical methods are often used to prepare high-quality ferrite materials. Such as salt mixed thermal decomposition method, chemical co-precipitation method, jet combustion method and electrolytic co-precipitation method. The chemical method can overcome the shortcomings of the powder metallurgy method that the solid phase reaction is not easy to perfect, the powder is unevenly mixed, the separation is not easy to be too fine, and the activity of the raw material has a great influence on the product performance, so that the performance of the ferrite material can be significantly improved. The disadvantage is that the cost is high and the process is relatively complicated.

Send Inquiry